ESRF – Particle accelerator facility

Initial results taken at the ESRF facility backed up our hypothesis: microscopic pockets of water molecules are responsible for ceramic product failures, and these defects are detectable before oven/kiln baking.

Microscopic analysis using X-ray tomography

To understand why products are failing in this manner, a hypothesis was formed that problematic arrangements of either water or air must be present inside the terracotta or ceramics. Expansion of these water or air pockets in high temperature ovens would account for the product failures.

Initial research has been performed using X-Ray tomography to understand the internal molecular structure of variously prepared terracotta samples. A specific arrangement of water/air pockets was found in moulded clay samples. This confirmed the initial hypothesis, and added a new data point regarding the concentration and arrangement of the pockets.

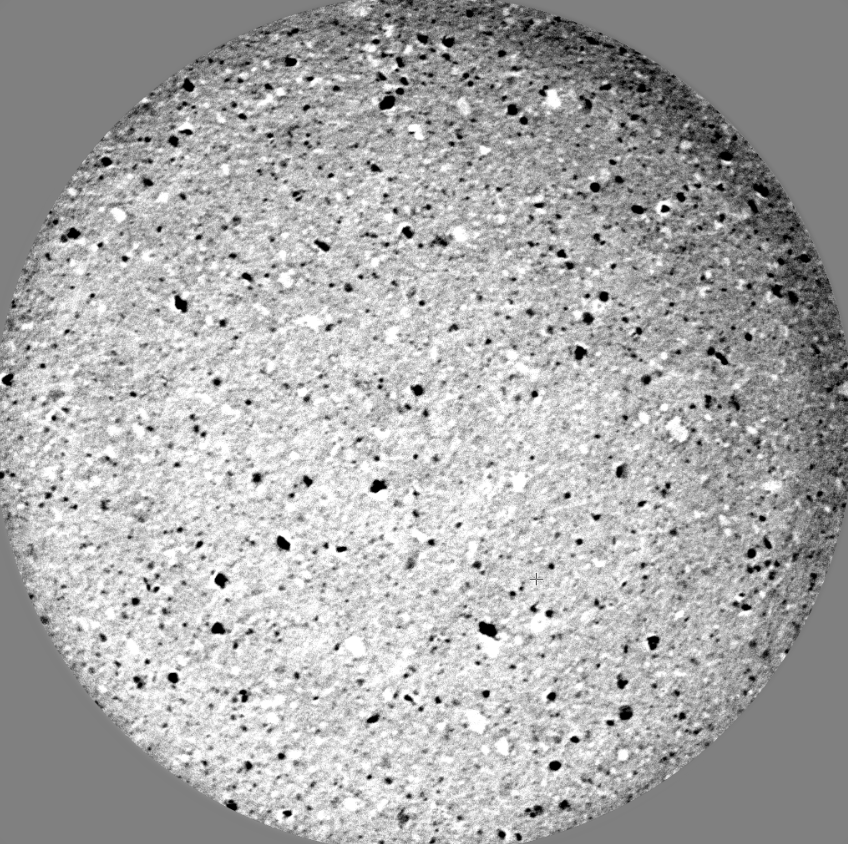

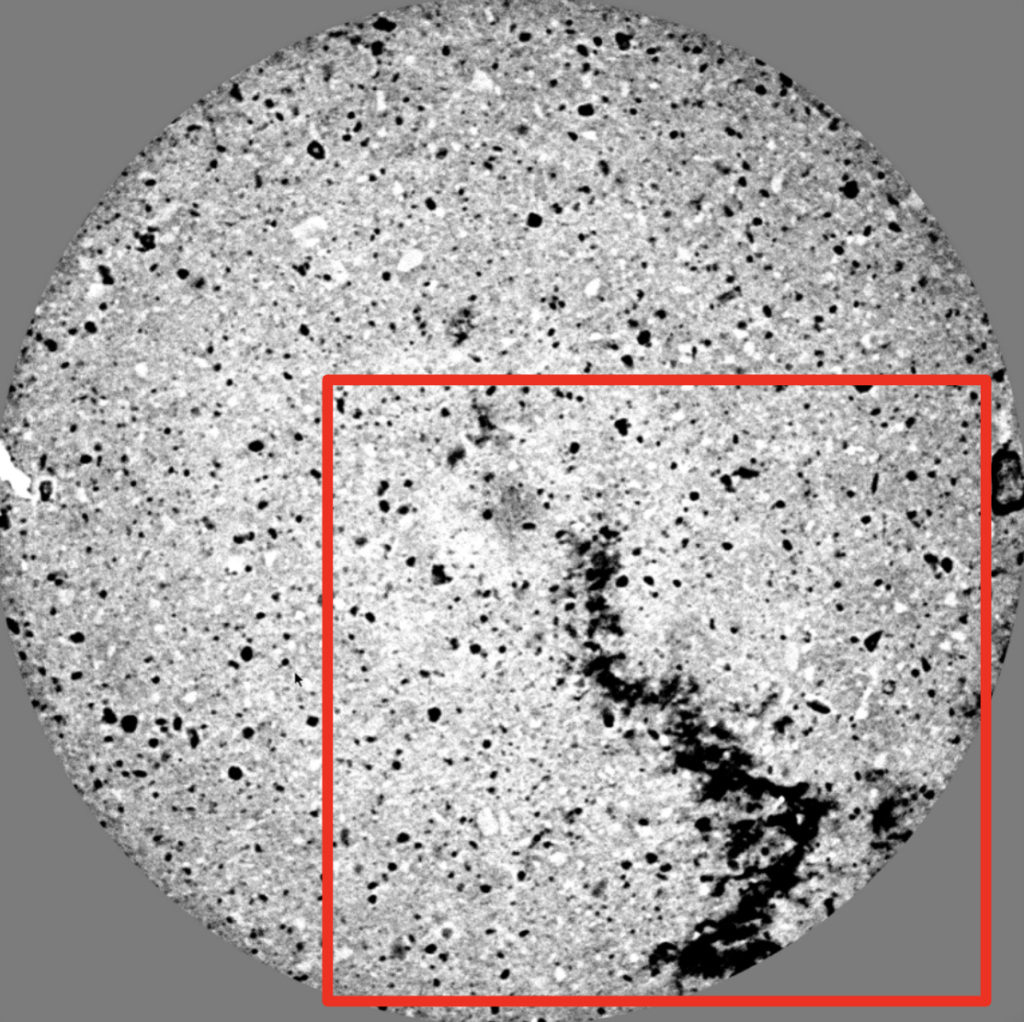

Using X-ray tomography, we were able to identify problematic areas of interest in ceramic samples

Control sample, water / air pockets are arranged in a regular, non-problematic manner. This sample would not experience critical failure when baked.

Problematic sample. The linear arrangement of air/water pockets expands when baking, causing cracks or explosive product failure.

This is a new scientific discovery – we’re eager to develop it further

Supporting the circular economy

Based on positive results from the initial experiment at ESRF under the Tamata research programme, we have been entered into the EU-funded ReMade programme.

This competitive programme funds scientific research for businesses who positively impact the circular economy, and is part of several EU initiatives aimed at sustainability and reducing environmental impact.